Cylinder Head Services

Cylinder Head Services

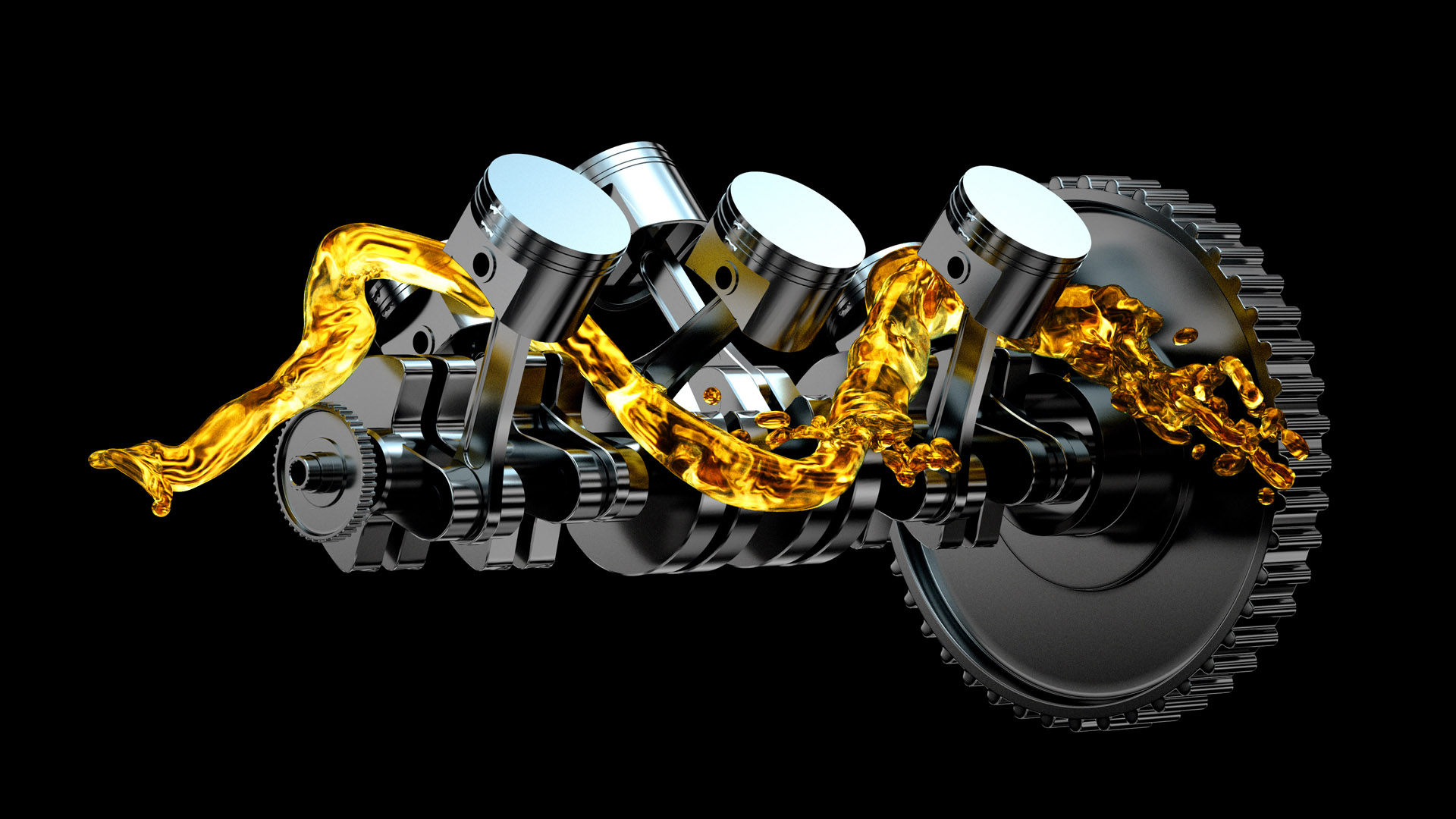

Precision Cylinder Head Repairs & Replacements for Maximum Engine Efficiency

- Trade Customers Welcome.

- Stringent Quality Control.

- Affordable & Transparent Pricing.

- Collection & Delivery Service Nationwide.

- Restore Engine Performance.

- Expertly Refurbished or Replaced.

GET A FREE QUOTE

What are Cylinder Head Services?

The cylinder head plays a crucial role in engine performance, housing essential components like valves and camshafts. Over time, wear and overheating can lead to cracks, warping, or valve failures. Our expert cylinder head services include full inspections, resurfacing, pressure testing, and valve seat refacing to restore optimal engine function.

Our Process

At every step of our reconditioning service, we follow a meticulous and proven process to ensure your engine cylinder head performs at its best.

From initial inspection to final delivery, our team of experts uses advanced techniques and quality parts to restore your engine components to like-new condition.

Here’s a detailed look at the steps we take to bring your engine back to life.

Step 1

Inquiry & Estimate

Call us on 447441920179 or Get a FREE Quote online.

We’ll discuss your component issues and provide a quote for the Cylinder Head Services you require.

A quote & link to the booking form is sent by email for confirmation and to book the job into the workshop schedule.

Trade partners are welcome to drop off the engine parts at any time during working hours. A quote and time frame will be provided at drop off. Pre-payment is required.

Step 2

Disassembly & Cleaning

pon receipt of payment, we will promptly arrange for the collection or delivery of your engine cylinder head.

Once your cylinder head arrives at our workshop, our expert team will carefully disassemble it, breaking it down into its individual components for thorough inspection. Each part is assessed meticulously to ensure no detail is overlooked.

Cleaning Process

We utilise state-of-the-art techniques to clean every part of your cylinder head. This involves advanced processes designed to remove all contaminants, ensuring that each component is prepared for reconditioning.

-

Acid Cleaning

Your cylinder head parts undergo a hot tank cleaning process, which effectively removes years of accumulated dirt, grease, carbon, and corrosion. By eliminating these contaminants, we can thoroughly inspect the parts for any hidden issues, such as hairline cracks or other structural imperfections that may affect performance. -

De-coking

As part of our cleaning process, we ensure that all engine parts are free of carbon build-up. This is essential for refurbishing and repairing your cylinder head, as excessive carbon can impair engine function and performance. -

Skimming (Resurfacing)

During the reconditioning process, most parts will require resurfacing to restore their smooth, flat surfaces. Using dry milling techniques, we renew the surfaces of your parts, providing a high-quality finish and improving their overall functionality. This step is crucial to ensuring that your cylinder head performs at its best once reassembled.

Step 3

Pressure & Heat Testing

- Your cylinder head undergoes a pressure test at 150psi to detect any internal or external leaks.

- To further assess the pressure, we submerge your cylinder head in hot water at 60°C, simulating the engine’s operating temperature.

- This method is cost-effective and ensures that the head casting is intact and there are no issues with the cooling system, verifying that everything is functioning as it should.

- These process helps identify cracks that need to be addressed, and ensures durability and performance.

Step 4

Inspections & Components Replacement

- We conduct a thorough examination of every component of your cylinder head, inspecting for signs of wear, damage, breakage, or warping. This ensures that each part works harmoniously for the best engine performance. Any worn-out, non-functional, or missing components will be replaced with new or reconditioned parts, restoring proper sealing and compression.

- This may include:

- Valve guides replacement

- Valve Seats re-cutting

- Valves resurfacing

- New oil stem seals

Step 5

Reassembly & Testing

- After cleaning, resurfacing, repairing cracks, and replacing any faulty parts, your cylinder head is carefully reassembled to a high standard.

- Each component is put back together to the manufacturer’s specifications.

- During reassembly, valve clearance adjustments are also made to ensure proper function and optimal engine performance.

Step 6

Quality Control Checks & Collection or Delivery

- Upon receiving the balance payment, your engine cylinder head will undergo final quality control checks to ensure everything meets our strict standards.

- Once approved, it will be ready for collection. We offer nationwide delivery options to return your cylinder head to you in perfect working condition.

Call 447441920179 to book in your engine cylinder head service and enjoy peak performance with a warranty-backed solution.

We stand behind our work. Every engine cylinder head undergoes rigorous testing before it leaves our workshop, ensuring optimal performance and durability.

Specialists in Land Rover, Jaguar, BMW & MINI Engines

We are specialists in BMW reconditioned engines, MINI engine rebuilds, Jaguar engine reconditioning and Land Rover engine remanufacturing. Our team has extensive experience working with these marques, restoring engines to manufacturer standards while saving our customers up to 60% compared with main dealer quotes. Whether it’s a high-performance BMW straight-six, a MINI Cooper turbo, a Jaguar petrol V6, or a Land Rover diesel, we have the expertise to bring your engine back to life.

Engines for Other Leading Car Brands Too

Alongside our BMW, MINI, Jaguar and Land Rover expertise, we also recondition and rebuild engines for other popular car manufacturers. From Audi, Volkswagen and Mercedes to Ford, Vauxhall and beyond, we deliver the same high standards of engineering, reliability and value across a wide range of engines.

quick links

Quick Contact

- Office 478 Vienna, AU 92101

- 447441920179

- info@quikrepair.live

Copyright © 2025 All rights reserved.